Hydrophobicity Classification of Composite Insulators Using Convolutional Neural Networks

Authors

C.C. KOKALIS, T. TASAKOS, V. T. KONTARGYRI, G. SIOLAS, I. F. GONOS - National Technical University of Athens (NTUA), Greece

C. A. CHRISTODOULOU - Hellenic Electricity Distribution Network Operator S.A. (HEDNO), Greece

K.O. PAPAILIOU - Technische Universität Dresden, Germany

Summary

This paper refers to the hydrophobicity classification of medium voltage composite insulators using convolutional neural networks. The classification procedure is performed according to IEC Standard 62073 (§3.4 Method C – The spray method); using the spray method, 700 representative photographic images of the seven hydrophobicity classes were collected. In the current work, only brand new MV composite insulators of silicone rubber were used. Most of them were in the hydrophobicity class 2 and the rest in class 1. Therefore, solutions with different concentrations (0% -100% with a 10% step) of distilled water and ethyl alcohol were used to create artificially the remaining hydrophobicity classes. The above-mentioned images, which were used for neural network training, were not taken under specific conditions regarding shooting angle and distance from insulator, thus the images of the artificially sprayed insulators have no such limitations, consequently, such images can be taken faster and easier. Afterwards, the colored RGB images of the seven hydrophobicity classes were divided into three separate sets for each hydrophobicity class. The first set, consisting of 70 images of each category (70 × 7 = 490 images), was used to train the networks. The second one, consisting of 20 images of each category (20 × 7 = 140 images), was used to evaluate and validate the learning process and to compare the different models. The last one, with 10 different images of each category (10 x 7 = 70 photos), was used for the final evaluation of the models. Subsequently, three models of convolutional neural networks were trained, validated and tested for this specific classification task. These were: a small custom convolutional neural network, and two models, that were pre-trained on a large dataset of images. The recognition accuracy achieved by the best of the three networks was 84.29%. The advantages of this method can be concluded in a) easy and fast photographing process, b) short training time of the networks, c) satisfying recognition accuracy rate and d) ability of these networks to be deployed on embedded platforms and used in aerial applications for on-site inspecting composite insulators.

Keywords

Composite-insulator - Hydrophobicity-classification - Convolutional-neural-network - Image-processing1. Introduction

During the last decades, composite insulators have become increasingly prevalent in electricity networks around the world, both on distribution and transmission lines, considering their excellent performance in polluted environments, due to their hydrophobicity transfer mechanism, which contributes to hydrophobicity recovery preventing flashover and discharges on the insulator. The classification of composite insulators in hydrophobicity classes consists one of the well-known challenges faced by the power industry [1, 2].

In IEC Std. 62073 three methods for hydrophobicity classification of composite insulators are described: a) surface tension method, b) contact angle method and c) spray method. The first two methods cannot be applied in the field because they require specialized equipment and laboratory conditions. In contrast, the spray method is the only method, which can be used to measure hydrophobicity in the real operating conditions, because it is easy to be performed and requires simple equipment. According to this method there are seven hydrophobicity classes. Hydrophobicity class 1 represents the most hydrophobic insulators while hydrophobicity class 7 refers to the most hydrophilic insulators. The main concept of the spray method is that images of sprayed with distilled water insulators are taken and compared with several representative images of the Standard to determine the hydrophobicity class. A major problem of the spray method is that the result is strongly depended on human judgment during the phase of comparison with the representative images of the Standard [3, 4].

For this reason, considerable research on this particular field is in progress all over the world. Researchers are trying to find a solution on this classification problem by using pattern recognition algorithms, like neural networks [5, 6], in an effort to limit the involvement and the impact of human judgement.

The procedure that is followed in these cases consists of the following steps: 1) images of sprayed insulators for all the hydrophobicity classes have to be taken, 2) an image pre-process is executed to extract some characteristic features from images in order to train the neural network, and, finally, 3) the neural network is trained with these features and learns to classify new, unseen images in the correct hydrophobicity class. Some researchers have also tried to make integrated devices that can do all this work in the field [7, 8, 9, 10].

In this paper, a useful method on the hydrophobicity classification of composite insulators using convolutional neural networks and according to IEC Std. 62073 is applied. The most important benefits of this method are:

- The accuracy in this classification task is very high (approximately 85%).

- The time that is needed for the neural networks to be trained is very short.

- There is no need for a feature extraction process on images, before the training of the neural network; input of these networks is the pixels of images.

- There are no limitations and special requirements in the way that images are taken (angle and distance of picture shooting).

- It is not required a high quality on images that are used. These networks are responding very well also with low quality images.

- These networks can be integrated in a portable platform and be used in aerial applications.

2. Image collection

2.1. Equipment used

For the purposes of this paper the following equipment was used:

- A spray bottle as it is mentioned in IEC Std. 62073 to apply the mist of water on the insulators.

- Distilled water.

- Ethyl alcohol.

- A Nikon D3200 camera.

- Two medium voltage (24kV) suspension composite insulators. The surface under test was the first shed of insulators, which was manufactured with silicone rubber. The insulators were red colored.

2.2. Image collection procedure

This research relies on the IEC Std. 62073, §3.4 (Method C – The spray method). According to the Standard, a composite insulator is sprayed with distilled water for 10 s – 20 s from a distance of 20 cm ± 10 cm using a common spray bottle. Consequently, an image of the sprayed insulator is taken within 10 s and it is compared with some representative images of the Standard to make a decision to which of the seven hydrophobicity classes it belongs to. Also, there are some criteria, regarding to the shape of droplets and the surface that is covered with water, which must be taken into consideration to determine the hydrophobicity class of the insulator. These criteria are listed in Table I.

| HC | Description |

|---|---|

| 1 | Only circular shaped discrete droplets |

| 2 | Only discrete droplets, most of which are still normal in shape but deflected from circular shape |

| 3 | Only discrete droplets, most of which are irregular in shape |

| 4 | Discrete droplets. Less than 10% of the surface covered with water runnels |

| 5 | Discrete droplets. Between 10% and 90% of the surface covered with water runnels |

| 6 | More than 90% but less than 100% of the surface covered with water runnels |

| 7 | 100% of the surface covered with water |

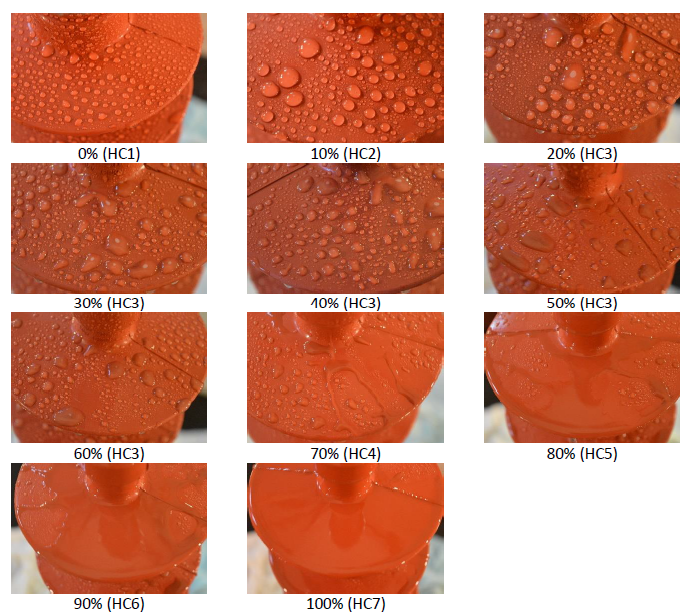

In the current work, 100 RGB colored photographs of sprayed insulator for each hydrophobicity class were taken. In total there were 700 photographs. The test surfaces for these experiments were the first sheds from the top of two red colored MV silicone rubber insulators. The insulator to be sprayed was positioned vertically, as it would be under operating conditions. Photographs were taken on non-energized insulators. Due to the fact that only brand new (unused) medium voltage composite insulators of silicone rubber were available, which belonged to hydrophobicity class 1 and 2 respectively, there was the need of artificial creation of the other hydrophobicity classes. Therefore, solutions of distilled water and ethyl alcohol with different concentrations (0% -100% with a 10% step) were used to construct artificially the remaining hydrophobicity classes. Figure 1 shows these artificially constructed hydrophobicity classes [11].

The above-mentioned photographs, which were used for neural network training, validation and testing, were taken under no specific conditions and requirements regarding the angle of photo shooting and the distance from insulator under test. Thus, the photographs of the sprayed insulators that are going to be evaluated have no such limitations and as a result, these photos can be taken faster and easier. Finally, the dimensions of the photos taken for the purposes of this research were (height, width) = (2000, 3008) pixels and before they were used to be fed to neural network, they were downscaled to much smaller dimensions: (height, width) = (300, 450).

3. Convolutional neural networks

3.1. Basic operation principle of convolutional neural networks

One distinct type of deep learning neural networks is Convolutional Neural Networks (CNN). CNN are based on the use of convolution operation. More specifically, convolution operation is a mathematical operation between two arrays. The former array of them is usually a filter or a kernel and the latter is a patch of the image fed to the neural network as training input or the image that comes of some transformations applied to the initial image.

Figure 1 - Artificial creation of the seven hydrophobicity classes of composite insulators using distilled water and ethyl alcohol solutions with different concentrations (0% -100% with a 10% step)

In particular, the main concept of training procedure of CNN is an adjustment of the weights of the above-mentioned filters. For this reason, during training of CNN there are several layers in succession. At each layer the convolution operation is applied to fixed sized patches of the image. Output of each layer is the input of the next layer. In this way, the weights of CNN mentioned above are adjusted to the specific images that are given to the network for training [12].

One main characteristic, which is also an advantage of CNN, is the fact that during training procedure they are fed with an image and there is no need for a feature extraction process on this image. In the vast majority of literature on the same classification task, a feature extraction pre-process of training images takes place before these images are fed as input to the neural network. CNN needs the image as it is and afterwards, during training procedure, the weights of CNN are adjusted with the use of convolution operation [13].

3.2. Tested architectures of convolutional neural networks

For the purposes of this paper two CNN architectures were tested:

- A small custom CNN consisting of 4 convolutional layers. This CNN was used firstly to give a first result on how convolutional neural networks respond to the hydrophobicity classification task of composite insulators and afterwards to determine an appropriate size of the input images which should be enough smaller than the initial image size (height, width) = (2000, 3008).

- VGGNet architectures (VGG16 and VGG19) with pretrained weights on a large set of images called ImageNet, whose output layer had the ability to be modified and trained in order to predict hydrophobicity classes of composite insulators. VGGNet was created by VGG (Visual Geometry Group) from Oxford University. Although VGGNet was the runner – up (not the winner) of the ILSVRC 2014 (ImageNet Large Scale Visual Recognition Competition) [14].

3.3. Data processing and hardware used

In this research, the colored RGB images of the seven hydrophobicity classes of composite insulators were divided into three separated sets for each hydrophobicity class. The first of them, consisting of 70 images of each category (70 × 7 = 490 images), was used to train the networks. The second one, consisting of 20 photos of each category (20 × 7 = 140 images), was used to evaluate-validate the learning course and to compare the different models. The last one, with 10 different photographs of each category (10 x 7 = 70 images), was used for the final evaluation and the extraction of recognition accuracy of the models.

Two different regularization techniques, called templates in the literature, were used to train the networks effectively. These were data augmentation and dropout. Data augmentation is the procedure that changes slightly the initial training images after each training epoch (one epoch identifies a passage of all training data over the network). In this way, the CNN can learn the underlying representations characterizing each hydrophobicity class and not the specific training images. On the other hand, another usually used technique in problems like this specific classification task is the usage of a dropout rate in the neurons of the CNN. At each epoch a random set of neurons is excluded from the training process. This compels neurons to learn better and more powerful representations and features. Moreover, it reduces the hazard of memorization of training images. Furthermore, validation loss was calculated in combination with the training loss. When validation loss was not reduced, the training process was stopped. This is the reason why the CNN was trained on image set, called training set, but validated on an unseen image set, called validation set [15, 16].

The computer hardware used to conduct these experiments was as follows:

- CPU: Intel Xeon E5-26200 at 2.1 GHz

- GPU: 2 x GeForce GTX 1080

- Ram: 4 x 16 GB Kingston HyperX DDR4-2400MHz

Training time of each CNN was approximately half an hour.

4. Results on training and validation procedures

In this section the results of this work are presented, regarding the training and validation stages of the three tested CNN.

4.1. Small convolutional network

Initially, the appropriate size of the images, which were used, was determined. A small custom-made CNN was used for this purpose. Furthermore, a first investigation, on how the convolutional neural networks respond to the hydrophobicity classification problem of composite insulators, was conducted with the use of this small CNN. The results showed that a CNN can respond reasonably well in this specific classification task and that was the initial trigger for more research on this field.

In the figures, which are presented below, there are two indicators: training accuracy and validation accuracy. During training phases, training accuracy is calculated as the ratio of the correctly predicted training images to the total training images. In the same way, during validation stages, validation accuracy is calculated as the ratio of the correctly predicted validating images to the total validating images.

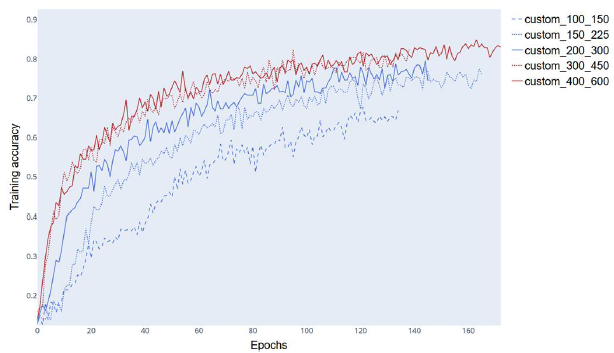

Figure 2 and Figure 3 illustrate the results linked with the small CNN. This custom CNN had 4 convolutional layers. The aforementioned techniques of data augmentation and dropout were used.

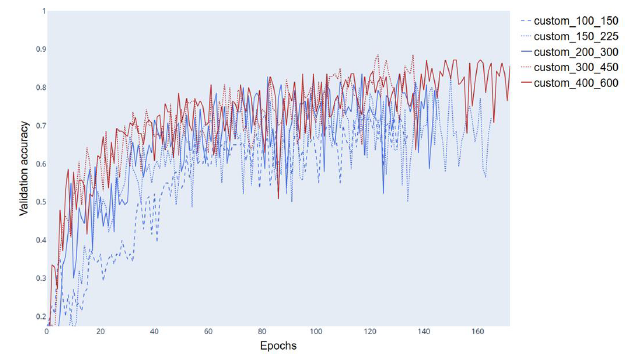

From Figure 2 and Figure 3 it can be noticed that as the size of images increases, the CNN has better results. Thus, in this research the image size (height, width) = (300, 450) was chosen to be used, because of its quite small size and its very good performance.

The results shown in Figure 3, seem to be noisier than them in Figure 2. That is because the network has never seen the validating images during training phase. Furthermore, it is observed that validation accuracy tends to be higher than training accuracy. This is due to the data augmentation technique used, which transforms heavily the training images (brightness adjustment, flipping, padding) and makes them more difficult to be classified than the non-transformed validation images.

Figure 2 - Custom model’s training accuracy with different image sizes (height, width)

Figure 3 - Custom model’s validation accuracy with different image sizes (height, width)

4.2. Pre-trained VGGNet architectures

In the literature, many different convolutional neural network architectures have been proposed. These architectures have been tested many times and thus exist as standard models in many deep learning frameworks such as Tensorflow or Keras. Two such models were used, namely VGG16 and VGG19, and applied directly to our data. These architectures are based on the VGGNet architecture [14] with the first having 16 convolutional layers and the second having 19.

VGG16 and VGG19 models were trained on ImageNet, a very large dataset of thousands of classes and millions of real-world images, to be able to recognize and classify real world representations. Therefore, in this research, these two models were used and tested with the weights of their convolutional layers unchanged. Only their last convolutional layers were adjusted to adapt to our specific hydrophobicity classification task of composite insulators.

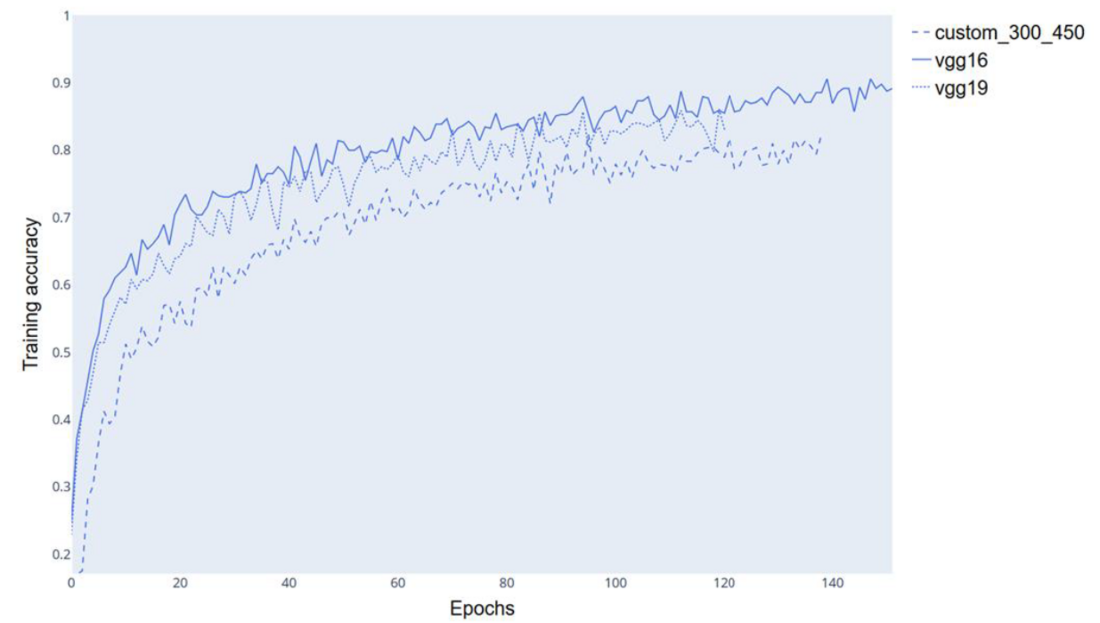

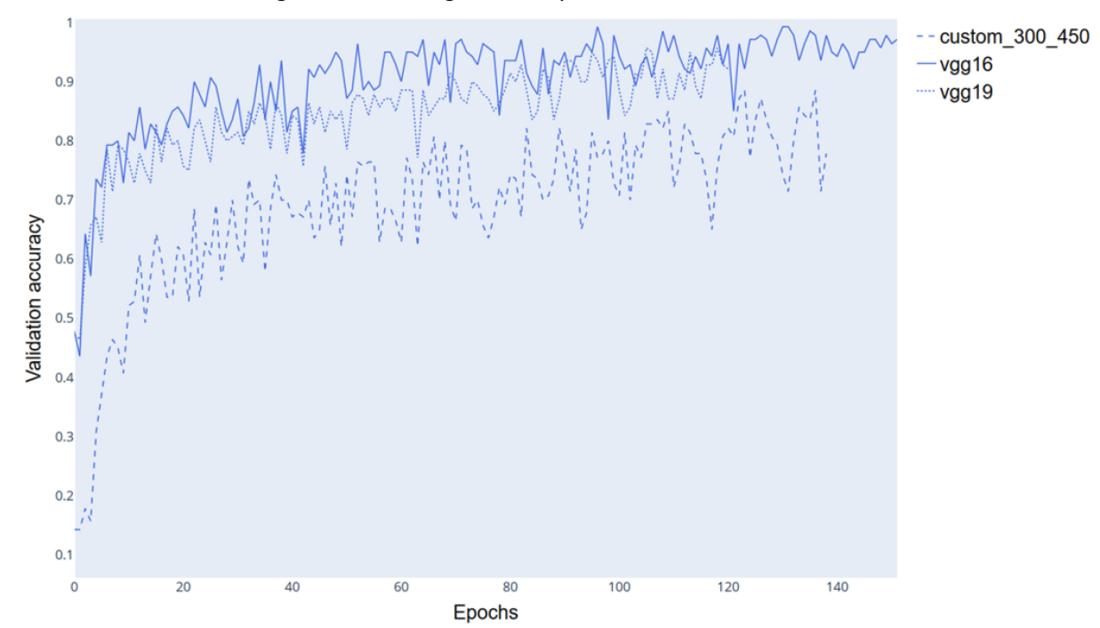

Figure 4 - Training accuracy of the three tested CNN

Figure 5 - Validation accuracy of the three tested CNN

From Figures 4 and 5 it is illustrated that VGG16 and VGG19 have better performance than the small custom model, with VGG16 being the best. VGG16 and VGG19 models can learn more complicated representations because of their deeper architecture and their pre-adjusted weights. These weights seem to be quite consistent with this hydrophobicity classification problem.

In addition, graphs in Figure 5 are noisier than them in Figure 4 and validation accuracy is higher than training accuracy due to the same reasons presented in §4.1.

5. Results on test set of images

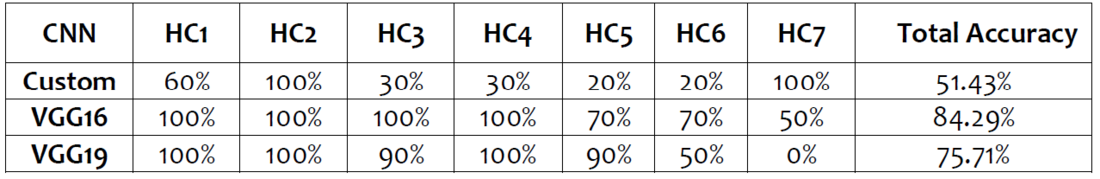

Ιn this section the three CNN models are tested on the images of the test sets to extract the final recognition accuracy. There were seven sets of ten images each one. Each set includes representative images of the seven hydrophobicity classes. The basic characteristic of these images was that they were not seen before by the three CNN tested. Thus, testing the networks with such images ensures more reliable results regarding their recognition accuracy. Τhe results presented in Table II indicate that the VGG16 CNN had the best performance with an 84.29% total accuracy.

Table 2 - Recognition accuracies of the tested CNN for all hydrophobicity classes and the total accuracies

Table 2 contains the accuracy for each hydrophobicity class, calculated as the ratio of correctly predicted test images to total test images and total accuracies as the mean value of the seven accuracies for each tested model.

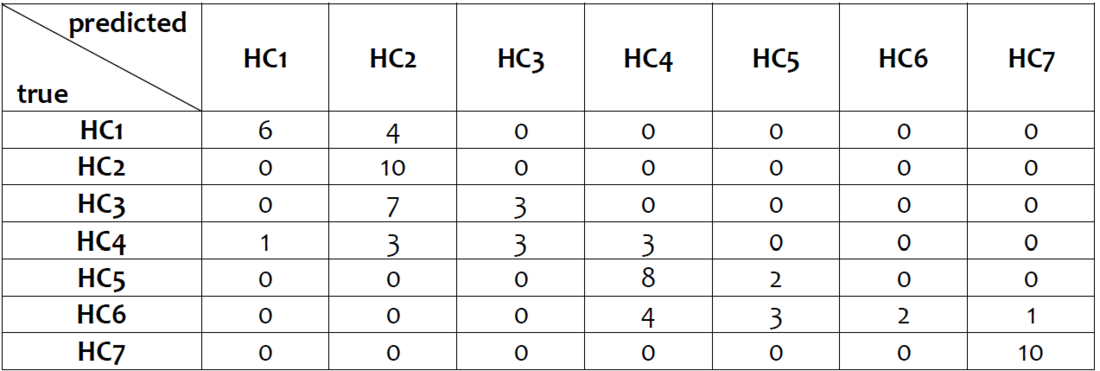

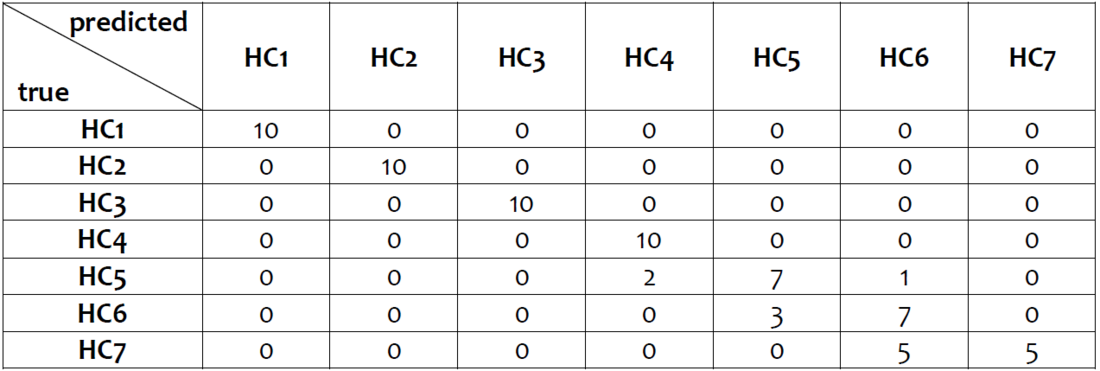

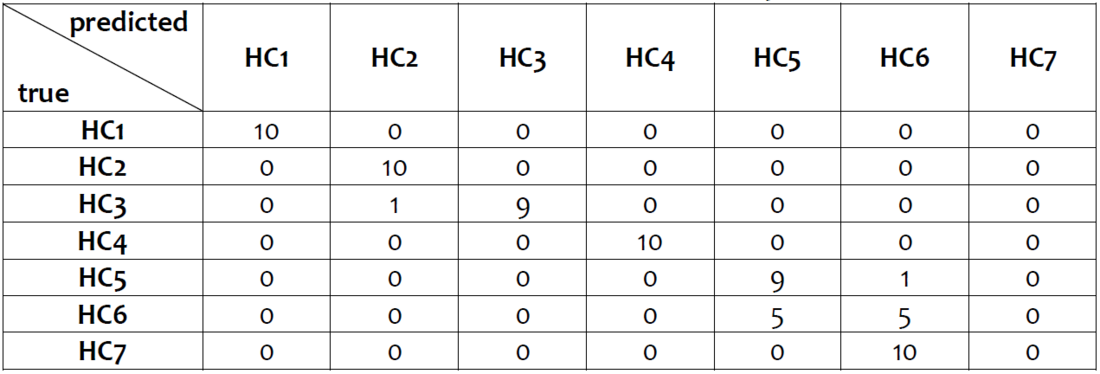

Table 3, Table 4 and Table 5 are presented in order to present a better view regarding the misclassification errors of these three models.

Table 3 - Confusion matrix for the custom CNN

Table 4 - Confusion matrix for the VGG16 CNN

Table 5 - Confusion matrix for the VGG19 CNN

Results in Tables 3-5 indicate that when a misclassification error occurs, the hydrophobicity class is confused with its adjacent hydrophobicity classes, more often the next or the previous one. Thus, the robustness of the three models, especially of VGG16 (Table 4) is justified.

6. Conclusions

In this paper the hydrophobicity classification problem of composite insulators using convolutional neural networks has been investigated. For the purposes of this work, 700 images of the seven hydrophobicity classes were used. Specifically, 490 pictures were used to train the networks, 140 images to be used in the validation stage and 70 images to extract the total recognition accuracies of the networks. Furthermore, three convolutional neural networks were used: a small custom CNN with 4 convolutional layers, the VGG16 CNN with 16 convolutional layers and the VGG19 CNN with 19 convolutional layers. The best total accuracy of almost 85% was achieved by the VGG16 CNN.

The main advantages of the proposed method are the following:

- The total accuracy in this classification task is 84.29% and achieved by the VGG16 model.

- The training time of these networks is very short.

- Feature extraction procedure on images is not needed before training process. This results in time and hardware resources savings.

- There are no special requirements regarding the angle and distance when taking photographs of the sprayed composite insulators.

- Low quality images can be used.

- This method can be used in aerial applications of composite insulator inspection.

Taking all the above into consideration, it is inferred that the proposed method is a useful tool for the classification of composite insulators into hydrophobicity classes restricting the subjectivity of human judgment. In addition, it is noted that further research in this field is needed to achieve better results in the total recognition accuracies of convolutional neural networks models.

References

- S. Yanga, Z. Jia, X. Ouyang, H. Bai and R. Liu, “Hydrophobicity characteristics of algae-fouled HVDC insulators in subtropical climates”, Electric Power Systems Research, vol 163, pp. 626-637, October 2018.

- M. Berg, R. Thottappillil and V. Scuka, “Hydrophobicity Estimation of HV Polymeric Insulating Materials Development of a Digital Image Processing Method”, IEEE Transactions on Dielectrics and Electrical Insulation, vol 8, no. 6, pp. 1098-1107, December 2001.

- Guidance on the measurement of hydrophobicity of insulator surfaces, IEC TS 62073 Ed. 2.0, Feb. 2016.

- K. Yan, F. Wang, Z. Zhang, N. Li and F. Lv, “Edge Detection of Composite Insulators Hydrophobic Image Based on Improved Canny Operator”, Energy and Power Engineering, vol 5, no. 4B, pp. 593-596, Jul. 2013.

- I. Jarrar, K. Assaleh and A. H. El-Hag, “Using a Pattern Recognition-Based Technique to Assess the Hydrophobicity Class of Silicone Rubber Materials”, IEEE Transactions on Dielectrics and Electrical Insulation, vol 21, no. 6, pp. 2611-2618, Dec. 2014.

- B. Wang, H. Ninghui, S. T. Liu and W. Long, “Hydrophobic Detection Study of Composite Insulator Based on BP Neural Network Grading”, The Open Automation and Control Systems Journal, vol 7, no. 1, pp. 960-965, Aug. 2015.

- Q. Wang, Y. Huang, X. Mo, W. Lai, H. Dong, Υ. Yang, J. Liu, J. Huang and Y.Sun, “The Study of the Improved Multilayer Perceptron Algorithm on Hydrophobicity Detection Research of Composite Insulator Bushing”, 8th International Conference on Intelligent Human-Machine Systems and Cybernetics, pp. 438-441, 2016.

- Q. Sun, F. Lin, W. Yan, F. Wang, S. Chen and L. Zhong, “Estimation of the Hydrophobicity of a Composite Insulator Based on an Improved Probabilistic Neural Network”, Energies, vol 11, no. 9, Sep. 2018.

- L. Yang, J. Bi, Y. Hao, L. Nian, Z. Zhou, L. Li, Y. Liao, F. Zhang, “A Recognition Method of the Hydrophobicity Class of Composite Insulators Based on Features Optimization and Experimental Verification”, Energies, vol 11, no. 4, Mar. 2018.

- L. Zhao, C. Li, J. Xiong, S. Zhang, J. Yao and X. Chen, “Online Hydrophobicity Measurement for Silicone Rubber Insulators on Transmission Lines”, IEEE Transactions on Power Delivery, vol 24, no. 2, pp. 806-813, Apr. 2009.

- R. Jayabal, K. Vijayarekha and R. S. Kumar, “Design of ANFIS for Hydrophobicity Classification of Polymeric Insulators with Two-Stage Feature Reduction Technique and its Field Deployment”, Energies, vol 11, no. 12, Dec. 2018.

- C. Szegedy, V. Vanhoucke, S. Ioffe, J. Shlens and Z. Wojna, “Rethinking the Inception Architecture for Computer Vision”, IEEE Conference on Computer Vision and Pattern Recognition (CVPR), pp. 2818-2826, 2016.

- Y. Lecun, L. Bottou, Y. Bengio and P. Haffner, “Gradient-based learning applied to document recognition”, Proceedings of the IEEE, vol. 86, no. 11, pp. 2278-2324, Nov. 1998.

- C. Szegedy, W. Liu, Y. Jia, P. Sermanet, S. Reed, D. Anguelov, D. Erhan, V. Vanhoucke and A. Rabinovich, “Going Deeper with Convolutions”, IEEE Conference on Computer Vision and Pattern Recognition (CVPR), pp. 1-9, 2015.

- N. Srivastava, G. Hinton, A. Krizhevsky, I. Sutskever and R. Salakhutdinov, “Dropout: A Simple Way to Prevent Neural Networks from Overfitting”, Journal of Machine Learning Research, vol. 15, pp. 1929-1958, Jun. 2014.

- A. Krizhevsky, I. Sutskever and G.E. Hinton, “ImageNet Classification with Deep Convolutional Neural Networks”, Proceedings of the 26th Conference on Neural Information Processing Systems (NIPS 2012), vol. 1, pp. 1097-11056, Dec. 2012.