AI-Augmented Systems for Enhancing Safety and Efficiency in Live Working of Electrical Overhead Transmission Lines

Authors

Janos TOTH - RecognAIse Technologies, Canada

Balint NEMETH, Levente RACZ, Gabor GÖCSEI - Budapest University of Technology and Economics, Hungary

Summary

This paper explores the integration of Artificial Intelligence (AI), particularly Large Language Models (LLMs), into the domain of live working (LW) on overhead transmission lines. Live-line maintenance is critical for maintaining grid stability and operational efficiency, especially under increasing demands for network resilience and uninterrupted service. However, this field faces mounting challenges, including a rapidly aging workforce and the pressing need to preserve and transfer tacit operational knowledge. Traditional knowledge management systems are often inadequate for capturing the depth and context of expert know-how required for safe and effective LW practices. This paper presents an AI-augmented knowledge management framework designed to support linemen in both preparation and fieldwork. The paper evaluates a technical demonstration using the Gemma 3 LLM, trained with CIGRE B2 materials, to assess its capacity to assist with a specific LW task: replacing dead-end insulators on 69 kV lines. The comparison between pre-trained and post-trained model responses reveals significant improvements in relevance, technical specificity, safety guidance, and task optimization. The findings underscore the potential of LLMs to serve as dynamic, secure, and context-aware knowledge tools in live-line operations, contributing to both workforce development and the long-term resilience of the electrical grid.

Keywords

Live-line maintenance, live working, artificial intelligence, Large Language Models, LLM, knowledge management, transmission lines, distribution lines1. Introduction and Background

Live-line maintenance, known as Live Working (LW), is increasingly popular worldwide. Live work involves performing maintenance, construction, or testing on equipment and circuits that are energized or may become energized [1]. This approach helps utilities avoid revenue loss and maintain the reliability and stability of the transmission grid [2]. However, to perform such work safely, workers must be well-versed in live work rules and regulations to ensure their safety and the safety of others. It is also crucial for workers to have accreditation, properly tested tools, and Personal Protective Equipment (PPE) for dedicated jobs [1]. The LW technology includes gloving, insulating tool work, and barehand methods, which have different advantages and disadvantages on networks of varying voltage levels (Figure 1).

Figure 1 – Different LW methods (gloving, insulating tool work, barehand) [3]

1.1. Necessity of Live Working

The LW technology minimizes consumer disruptions during maintenance and fault prevention tasks and offers numerous technical and economic advantages. Additionally, live working has more favorable accident statistics than maintenance performed in de-energized conditions. Managing distribution networks within a country and maintaining interconnections across countries or continents poses a significant challenge for network operators. Various methods exist to schedule fault prevention tasks based on different priorities. LW is a method for safely and economically executing planned tasks [2].

Ensuring operational safety, supply security, and long-term service quality requires a well-maintained, continuously and systematically managed network. De-energizing the network involves numerous additional tasks, whereas live working allows the network to operate normally, except for specific operational conditions required in some regions at different voltage levels. The LW approach ensures that maintenance can be carried out without interrupting the normal operation of the network, thereby enhancing overall efficiency and reliability [2].

1.2. Evolution of the technology

From the beginning of the 20th century, the evolution of live working built up as technical solutions were created for existing operating challenges (Figure 2). In the early days of electrical grid maintenance, the work was hazardous due to the lack of proper tools and safety measures. This danger motivated electricians and engineers to innovate, leading to the development of insulated materials. In the 1910s, the first insulated gloves and tools appeared, marking the beginning of safer live line maintenance practices. By 1916, the need to perform maintenance on energized circuits without service interruptions led to the creation of the "electrical hook," a spring-type clamp on an insulating stick. This innovation spurred the development of various specialized tools for handling energized parts more safely and efficiently. As the demand for uninterrupted power supply grew, utilities began permitting live work on higher-voltage lines. By 1930, live work was allowed on lines up to 66 kV, and by the late 1930s, successful live work on 220 kV lines demonstrated the feasibility of maintaining even higher-voltage lines while energized [4].

The introduction of fiberglass sticks in 1959 addressed the need for more durable and moisture-resistant tools. These sticks enabled safe maintenance on high-voltage lines up to 765 kV, significantly enhancing the safety and reliability of live line maintenance.

Figure 2 – Photos taken during LW jobs in the past [5]

In the 1960s, the barehand method was introduced in parallel in several countries worldwide, driven by the need for greater precision and safety in live work. This method allowed linemen to work directly on energized parts, advancing live working techniques. The creation of Portable Protective Air Gaps (PPAGs) in 1965 addressed the need to control temporary overvoltages, ensuring worker safety during live maintenance on high-voltage lines. This innovation allowed for safer and more efficient live work across various transmission voltages [4]. In the 2000s, the continuous need to improve safety, reliability, and efficiency in live working led to integrating aerial devices with insulating boom segments and various insulating tools, making live work procedures safer and more effective than ever.

2. Current Needs and Challenges

Based on the evolution of live working, a precise recognition of today's challenges can help to set directions that can open new chapters in the history of LW. Among the many challenges of today, two are worth highlighting: the extreme necessity for the grid's resilience operation and the aging of the linemen, which has increased the importance of an effective knowledge management system.

2.1. Reliable and Resilient Grid Operation

Resilience in power systems is essential to ensure uninterrupted energy delivery under stress conditions, including extreme weather events, component failures, cyber incidents, and the increasing complexity of modern grid operations [6]. Grid disruptions can propagate rapidly, impacting critical infrastructure and causing substantial economic and societal harm. Strengthening resilience requires not only physical infrastructure upgrades but also the implementation of operational strategies that maintain system availability and service continuity [7]. As previously detailed, live working provides a technical means to perform maintenance, inspection, and upgrade tasks without de-energizing transmission assets. This capability directly supports resilience objectives by minimizing planned outages, maintaining network topology during intervention, and enabling faster recovery from localized faults. LW facilitates proactive asset management and enhances operational flexibility, particularly in meshed or heavily loaded systems where outages would compromise redundancy or stability. This way, LW aligns with modern resilience frameworks by ensuring essential maintenance activities can be conducted without sacrificing system reliability.

2.2. Aging Maintenance Crew

The average age of utility linemen in the U.S. is approximately 45 years. This statistic indicates that a significant portion of the workforce is approaching retirement age, which could impact the availability of experienced personnel for critical tasks such as live working. Specifically, almost 70% of utility linemen are 40 or older, highlighting the potential for a skills gap as these workers retire [8].

This demographic trend underscores the importance of workforce development, training programs, and building up efficient knowledge management systems to ensure a steady pipeline of skilled workers in the high-voltage industry. As the current workforce ages, it is crucial to implement strategies that attract younger individuals to the field and provide them with the necessary training and experience. This will help mitigate the potential loss of expertise and maintain the reliability and safety of electrical grid operations.

2.3. Knowledge Management in the High-Voltage Industry

Knowledge management involves systematically capturing, distributing, and effectively using organizational knowledge. It becomes crucial in high utility engineering and linemen fields, where the workforce is aging rapidly. It ensures that older workers' valuable expertise and experience are documented and transferred to newer employees. This helps maintain operational efficiency and safety standards, even as experienced personnel retire. By implementing robust knowledge management systems, the industry can bridge the skills gap and sustain a competent workforce capable of handling the complexities of live working.

One of the primary challenges in establishing a classical knowledge management system in the power industry is the lack of properly documented knowledge [9]. There is often a significant gap between workers' extensive field experience and what is formally recorded. Much of the critical expertise resides with individuals rather than within company-owned resources, making it vulnerable to loss when employees retire or leave the company.

Additionally, this knowledge is sensitive and cannot be shared on public or unsecured platforms, complicating documentation and dissemination. Therefore, new, adaptive solutions are required - approaches that not only address the technical aspects but also capture the broad spectrum of knowledge types essential for the sustainable operation of the electrical grid.

Knowledge management systems in high-voltage engineering must prioritize security to protect sensitive information, ensure accessibility to authorized personnel, and accommodate the practical realities of knowledge creation and transfer within the industry. By addressing these needs, the power industry can develop robust knowledge management systems that safeguard valuable expertise and support the continuous and reliable operation of the electrical grid.

3. Artificial Intelligence-Supported Live Working

One of the main characteristics of a well-built Knowledge Management System is that it is easy to use, provides practical, easily understandable knowledge to linemen at all career levels, and is well digitized. These characteristics suggest that a modern knowledge management system should exploit modern, up-to-date technological opportunities, such as artificial intelligence and large language models.

3.1. Introduction to AI and Large Language Models (LLMs)

Artificial Intelligence (AI) is revolutionizing various industries by enabling machines to perform tasks that typically require human intelligence, such as learning, reasoning, and problem-solving. AI technologies, including machine learning and natural language processing, can analyze vast data, identify patterns, and make highly accurate predictions [10]. This capability is crucial for optimizing processes, improving decision-making, and enhancing efficiency. AI's ability to predict equipment failures, optimize maintenance schedules, and manage grid operations is invaluable in high-voltage power engineering. By integrating AI, utility companies can ensure more reliable and resilient power line utilization, addressing both current challenges and future demands.

Despite the power system industry's conservative nature, AI-supported solutions have begun to emerge, even within the Community of CIGRE B2. The CIGRE Working Group B2.93 was established to tackle the challenges and opportunities of using AI for power line asset management, particularly focusing on image-based transmission line inspection automation using AI [11]. Its mission is to explore, evaluate, and promote AI-based methods to enhance overhead line inspection, maintenance, and operational efficiency. This initiative responds to the increasing complexity of transmission systems, the aging workforce, and the demand for smarter, more resilient grid operations. A key goal is to provide a structured framework for integrating AI technologies into asset management practices, such as image recognition, machine learning, and data analytics.

One special area of AI of the Large Language Models (LLMs) and multimodal systems presents transformative opportunities in most industrial fields. These technologies enable the seamless integration of textual, visual, and contextual data into unified frameworks, capturing and organizing intricate, domain-specific knowledge with greater precision and efficiency [10]. LLMs can support employees by assisting with technical inquiries, enhancing decision-making, and serving as robust platforms for managing and distributing knowledge across organizations.

3.2. Application of LLMs in Live Working

Live working ensures reliable and resilient grid operations. Effective knowledge management becomes essential to maintain operational efficiency and safety as the workforce ages. Large Language Models (LLMs) can play a significant role in this context by providing robust knowledge management solutions. However, the effectiveness of these systems depends on how they are trained and implemented.

The concept involves utilizing a non-public AI model, trained with technical information, to create a framework that linemen can use both before work and in the field. This solution helps workers better prepare for tasks, suggests appropriate working methods for new challenges, and highlights important safety aspects. It can adapt existing working methods to different countries with varying standards and rules, and assist young linemen in gathering necessary information and briefings for job preparation. This approach ensures better continuity in knowledge management and provides valuable assistance to less experienced personnel.

AI can support LW in several key areas:

- Dynamic Knowledge Management: LLMs can organize, store, and provide on-demand access to comprehensive knowledge bases, including clearance requirements, recommended equipment, and procedural guidelines for live-line activities. By centralizing this information, the system reduces cognitive load and ensures personnel have real-time access to critical data.

- Task Optimization: AI-powered recommendations offer context-specific advice on the most appropriate live working methods—hot glove, hot stick, or bare hand—for a given task. These recommendations are tailored based on system conditions, crew expertise, equipment availability, and site-specific constraints, ensuring optimal operational outcomes.

- Safety Assurance: Ensuring compliance with safety standards is paramount in live-line maintenance. The system can check for Minimum Approach Distances (MAD) and potential hazards, providing real-time alerts to maintenance crews. By proactively identifying risks, the system enhances worker safety and minimizes the likelihood of accidents.

- Crew and Resource Coordination: The system manages detailed information about crew capabilities, training records, and equipment inventories. This allows for practical task assignments aligning with crew expertise and resource availability while addressing site-specific opportunities and constraints.

By integrating AI into live line maintenance practices, the power industry can significantly improve knowledge sharing, support better decision-making, and strengthen operational resilience. This approach addresses the challenges of an aging workforce and enhances grid operations' overall efficiency and safety.

3.3. Demonstration of AI in Live Working

Initially not trained with technical details, an LLM model was selected to demonstrate the AI-augmented knowledge management system. A specific live working task - changing dead-end insulators on a 69 kV grid—was chosen for the demonstration (Figure 4). The model was then trained using technical documents, including papers and brochures from the CIGRE B2 collection. The same question regarding the task was posed to the system before and after training, and the answers were compared. This comparison was conducted by specialized live working trainer engineers, providing an overview of the model's capabilities. The evaluation highlighted the model's ability to understand and apply technical knowledge, demonstrating its potential to effectively enhance knowledge management and support live working tasks.

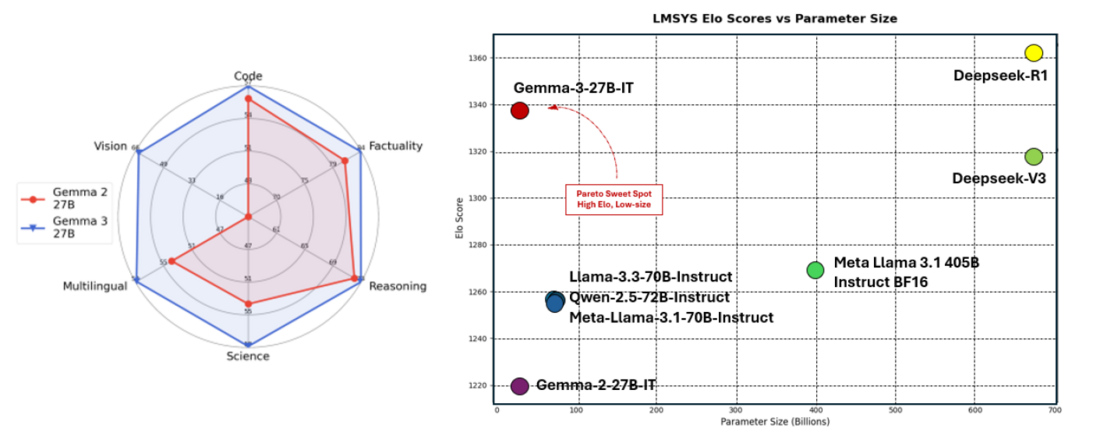

An essential part of the demonstration is choosing the proper LLM model. For this project's Artificial Intelligence testing, the Gemma 27B model was selected (Figure 3) [12][13]. This decision followed the introduction of Gemma 3 on March 12, 2025, representing a significant advancement in open-weight large language models. Gemma 3, with its 27 billion parameters, builds upon the research and technology of the Gemini models, achieving state-of-the-art performance across numerous benchmarks [14].

Figure 3 – Summary of the performance of different pre-trained models from Gemma 2 and 3 across general abilities (left); Gemma 3 27B is in the pareto sweet spot (right) [12]

A key feature of Gemma 3 is its enhanced multimodality, allowing it to process both text and image inputs and generate text outputs. The larger versions of the model feature an expanded context window of up to 128,000 tokens, enabling the processing of longer documents and more complex reasoning tasks. Additionally, Gemma 3 supports over 140 languages, making it a versatile tool for global applications, including text generation, image understanding, and multimodal reasoning [12].

The Gemma 3 model boasts a high Elo score using less than 50 billion parameters. Adapted from chess, the Elo score ranks models by their relative performance in AI evaluation through pairwise comparisons. A higher Elo score indicates a stronger model, and the system updates scores dynamically as new comparisons are made, providing an evolving measure of model performance [12].

Interaction with the Gemma 3 model is text-based. All input is typed text, and responses are generated as text. This allows for a direct and focused exchange of information through written language, facilitating efficient communication and utilizing the model's capabilities.

Gemma 3 can also run on a powerful personal computer. Thus, the system can operate independently from the Internet and can be fully secured for privacy, data protection, and physical security reasons.

A desktop computer was used for the AI evaluation with the following characteristics:

- Operating System: Microsoft Windows 10 Professional, System type x-64,

- Processor: AMD Ryzen, Threadripper, 2920X, 12 Core processor, 3500 MHz, 12 Cores, 24 Logical processors, 24 Logical Processors

- Physical Memory (RAM): 64 GB

- Two NVIDIA GeForce RTX 2080 Ti (with 11 GB of Graphical Memory) Graphics cards

3.4. Evaluation of the Demonstration

As mentioned in the earlier chapter, the LLM model was asked a single question before and after the training:

Can you provide information on replacing a dead-end insulator on a 69 kV transmission line using live working methods?

Figure 4 – Replacing insulators on a 132 kV power line [3]

The model’s initial response (untrained) provided a general overview of replacing a dead-end insulator on a 69 kV transmission line using live working techniques. It emphasized the complexity and danger of the task, stressing the importance of extensive training, experience, and adherence to company-specific procedures. The answer included detailed steps for planning and preparation, specialized tools and equipment, and a step-by-step outline of the live line replacement procedure. However, it lacked specific references to technical documents and case studies, making it less precise and tailored to the task.

The trained model's response was more structured and specific, incorporating information from technical documents and case studies from the CIGRE B2 collection. The answer outlined methods available for the task, such as the hot-stick and barehand methods, and provided detailed approaches and considerations based on case studies. The answer included specific citations from CIGRE documents, enhancing its credibility and relevance. It also highlighted important safety considerations and outlined the steps involved in the hot stick method, which is most likely applicable for the task.

The key points of the comparison before and after training are summarized in Table 1.

| Aspect | Untrained AI model | Trained AI model |

|---|---|---|

| Working method | Hot-stick method | Hot-stick method (proposed) Barehand method (listed as an option) |

| Safety consideration | Emphasized the need for risk assessment, job briefing, and adherence to safety protocols. | Emphasized insulation, maintaining clearances, avoiding inclement weather, clear communication, qualified personnel, and detailed planning. |

| Necessary steps | Listed, almost correctly | Listed, almost correctly |

| Necessary tools | Listed, including a bucket truck and insulated tools | Listed, including a bucket truck and insulated tools |

| Importance of authorization | Noted | Noted |

| Case studies from the reference | No | Yes |

As an overview, it can be said that the trained model's response is superior for several reasons:

- Specificity and Relevance: The trained model provided more specific and relevant information, including references to technical documents and case studies, which enhanced the response's accuracy and applicability.

- Structured Approach: The trained response was better organized, with clear sections on methods, safety considerations, and step-by-step procedures, making it easier to follow and implement.

- Credibility: The trained model's answer is more credible and authoritative because it cites specific sections from CIGRE documents, giving users confidence in the information.

- Safety Emphasis: Both responses emphasized safety, but the trained model included more detailed safety considerations and protocols, which are crucial for live line maintenance tasks.

- Task Optimization: The trained model offered context-specific advice on the most appropriate live-line methods, tailored to the task and conditions.

The consensus is that the trained AI model performs better overall, but the untrained model also provides a good summary. However, it is essential to note that both models exhibited some level of hallucination on technical points. This issue can only be mitigated if the user has expertise in the field. The level of hallucination can be reduced with a more extensive training dataset. Neither model provided exact values for safety distances, which is beneficial as it avoids the risk of incorrect values. However, including correct values could enhance the quality of the responses. Overall, AI cannot replace humans at this stage but can support their tasks effectively.

4. Conclusion

The application of AI in live working represents a transformative step for modern power systems. Utilities can perform maintenance with increased accuracy, reduced downtime, and enhanced worker safety by leveraging advanced algorithms, data analysis, and autonomous systems. This is particularly crucial given the increasing necessity for grid resilience and the challenges an aging lineman workforce poses, which necessitates effective knowledge management systems. While technical and regulatory challenges remain, such as cybersecurity, data quality, system integration, and ensuring trust in AI-driven augmentation of knowledge management, the trajectory is clear: AI is poised to become a key enabler in the next generation of grid maintenance. Continued investment in AI research, pilot projects, and collaborative development across utilities and technology providers is essential to fully realize the benefits, address the constraints, and seize the opportunities of this innovation for a resilient, future-ready power grid.

References

- CIGRE Joint Working Group B2/B3.27. Live work – a management perspective. CIGRE Technical Brochure No. 561. Paris: CIGRE; 2013 Dec.

- Gábor G. A szakszemélyzet fokozott védelme nagyfeszültségű rendszereken végzett feszültség alatti munka során [doctoral dissertation]. Budapest (Hungary): Budapest University of Technology and Economics; 2016.

- Komaromi P. Live working method comparisons: Rubber glove work vs. hotstick work vs. barehand work. In: 2017 12th International Conference on Live Maintenance (ICOLIM); 2017 Apr; Budapest, Hungary. IEEE; 2017. p. 1–6.

- Electric Power Research Institute (EPRI). Live work guide for overhead lines. 3rd ed. Palo Alto (CA): EPRI; 2004 Nov. Final Report.

- Devantine L. RTE – Live working, a cutting-edge technique: 50 years of French history. SERECT.

- North American Electric Reliability Corporation (NERC). Reliability standards for the bulk electric systems of North America. Atlanta (GA): NERC; 2024.

- Electric Power Research Institute (EPRI). Enhancing distribution resilience: Opportunities for applying advanced technologies. Palo Alto (CA): EPRI; 2019. Report No. 3002017050.

- Zippia. Electrical line worker demographics and statistics in the US. Zippia.com. [Internet]. [cited 2025 May 4].

- CIGRE Working Group B2.39. Management guidelines for balancing in-house and outsourced overhead transmission line technical expertise. CIGRE Technical Brochure No. 744. Paris: CIGRE; 2018 Sep.

- Thakur K, Barker H, Pathan ASK. Artificial intelligence and large language models. 1st ed. Boca Raton (FL): CRC Press; 2024.

- CIGRE Working Group B2.93. Artificial Intelligence (AI) Augmented Image-Based Transmission Line Inspection and Condition Assessment TOR CIGRE; 2024

- Gemma Team. Gemma 3 technical report. arXiv [Preprint]. 2025.

- Google AI for Developers. Gemma 3 model overview [Internet]. 2025 [cited 2025 Apr 28].

- Hugging Face. Welcome Gemma 3: Google's all new multimodal, multilingual, long context open LLM [Internet]. 2025 [cited 2025 Apr 28].