Development of multi-function conductor

Authors

Yuta MATSUDA, Tomonori SHIRAISHI, Noriyuki TAKADA - TEPCO POWER GRID Inc., Japan

Nobuaki SUGA, Tadahiro TAKAHASHI, Taisei ENAKA - Sumitomo Electric Industries, Ltd, Japan

Summary

There is a variety of natural disasters such as earthquakes, snow, and typhoons in JAPAN, and various measures have been taken to protect transmission lines from these disasters.

Regarding snow, based on our past experience of transmission tower collapses and sleet jump caused on conductor, we have installed SR rings (snow resistance ring) on conductor to reduce the amount of snow that accumulates. However, this ring has the problem of taking a long time to install because the SR rings are installed one by one after conductor have been installed. Therefore, we tried to develop a new conductor with a special uneven shape that has the same snow accretion resistance as the SR ring by changing the shape of the wire.

We found that the conductor with the special uneven shape has snow accretion resistance in snow accretion test, but the wind pressure of the conductor was greater than that of a standard conductor. Therefore, we combined wires that can be expected to have a wind pressure effect and wires that can be expected to have snow accretion resistance in various patterns to develop a conductor with the best combination that has both effects.

Keywords

Conductor, Snow, Wind pressure, Development1. Introduction

Overhead power transmission lines are designed and outfitted to withstand a variety of external environments. In the case of Japan, experience with damage to equipment caused by the likes of typhoons, earthquakes and snow has led to the implementation of various countermeasures and forms response to that damage. Where snow is concerned, in the past, the nation has experienced electrical accidents due to tower collapses and sleet jump caused by the accretion of snow on conductor. In countering this, it has become standard practice to install SR rings (Snow-Resistant; see Fig. 1) and counterweights (see Fig. 2) on conductor. These SR rings have the function of allowing snow that has accrued on conductor to fall in pieces between the rings before it forms a snow tube. However, they must be installed manually at intervals of a several dozen cm by linesmen after conductor is placed. If it is possible to obtain snow accretionproofing effects by coming up with ideas for the surface shape of conductor without placing SR ring and counterweight on conductor, not only can the cost of materials and installation be reduced, but advantages can also be gained in terms of maintenance due to the inspection and repair of such fittings becoming unnecessary. Given this, we took on the challenge of developing conductor shaped to give them snow accretion-proofing performance.

Figure 1 - SR Ring

Figure 2 - Counterweight

2. Concept of Multi-Function Conductor

We established specifications for the conductor that meet the following conditions:

- The outer diameter, mass, and calculated cross-sectional area of the conductor must be designed to be roughly equivalent to those of ACSR/AC conductor with round wire strands, which are employed as standard in Japan;

- The shape of the conductor must result in air resistance that is the same as or lower than that of standard conductor;

- Wire strand construction must not require any special processing in manufacturing the conductor;

- The structure of conductor must have snow accretion characteristics that are conducive to preventing heavy snow accretion that grows as it slides along the surface of the conductor.

3. Examination of Conductor Shape

Heavy snow accretion occurs when snow continues to slide along the stranded wires of conductor and forms snow tubes. One method of preventing snow tubes from forming is to reduce the contact area between snow and conductor and allow the snow to fall as it slides along the stranded wires. In this examination, we considered reducing the contact area between snow and conductor to obtain snow accretion-proofing effects by giving the wire strands of the conductor a special uneven shape. We test-produced conductor with an uneven wire strand shape, conducted a snow accretion test using artificial snow accretion equipment and verified the effects of snow accretion-proofing characteristics. As a result, we gained clear perspective of the possibility of reducing the amount of snow accretion by up to roughly 50% over ACSR/AC conductor (without snow accretion-proofing rings). However, when the shape of the wire strands of the conductor is only uneven, a wind pressure test showed that the drag coefficient increased (At a wind speed of 40 m/s, the CD value of the Multi-Function conductor was approx. 1.1. That for ACSR/AC conductor was approx. 1.0.). For this reason, we testproduced conductor that combined smooth wire strands with low wind pressure effects and uneven wire strands with snow accretion-proofing effects. Four wire strands were found to be the minimum number of uneven wire strands that could provide snow accretion-proofing effects. Next, based on a structure consisting of four uneven wire strands, we test-produced 18 types of conductor with the number of outermost wire strands (15 and 16 strands) and the height of each wire strand as parameters. We verified whether wind pressure reduction effects were present through a wind pressure test. As a result, we verified that all 18 types of conductors have a drag coefficient of approx. 0.9 at a 40 m/s wind speed, which is the same as or lower than that of ACSR/AC conductor. Based on these results, we narrowed down our subject to six type of conductor taking into consideration the combination of conductor cross-sectional area and mass, conducted an artificial snow accretion test and, eventually, performed various characteristic tests on three types of conductor with 15 outermost wire strands.

4. Characteristic Tests

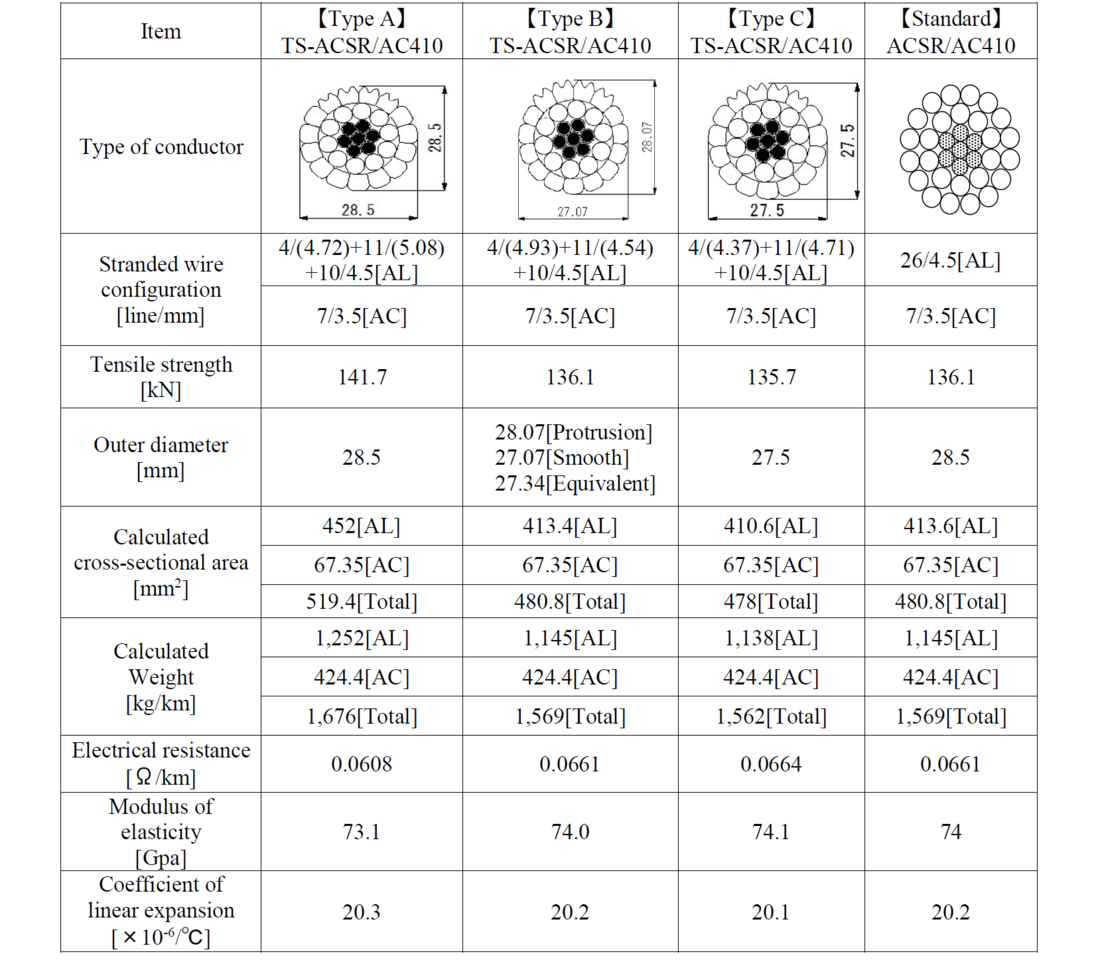

We performed the following various characteristic tests on the three types of conductor that we eventually narrowed down Type A, Type B and Type C (Table.1).

Table 1 - Conductor specifications

4.1. Wind Pressure Characteristic

[Test conditions]

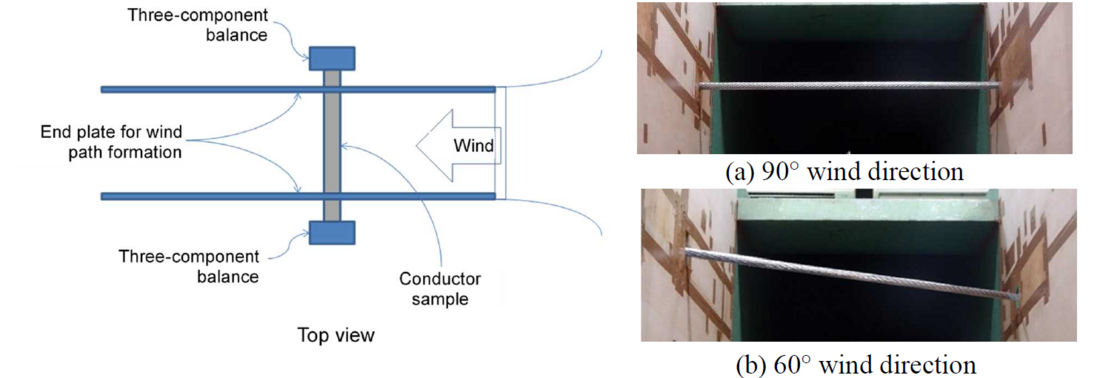

Using wind tunnel test equipment, we measured drag and lift forces with wind speed (10 m/s to 40 m/s) as a parameter (see Fig.3). We established wind direction angles as orthogonal (90°) and oblique (60°).

Figure 3 - Wind pressure test method

[Test results]

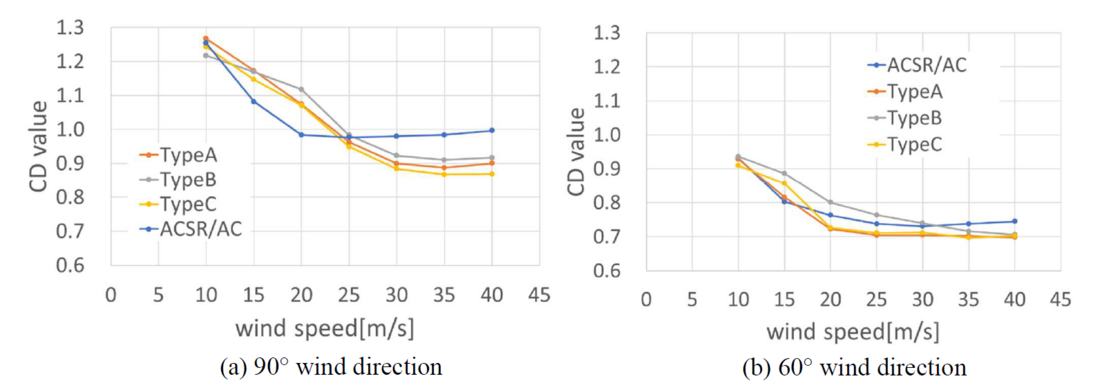

The orthogonal wind results and oblique wind results are shown in Fig.4, respectively. We verified that in orthogonal winds, the drag coefficient for all three types of multi-function conductor was approx. 0.9 at a wind speed of 40 m/s (Design maximum wind speed in Japan), which is the same as or lower than that of ACSR/AC (standard conductor). Additionally, we verified that even in oblique winds, the drag coefficient at a wind speed of 40 m/s (Design maximum wind speed in Japan) was the same as or lower than that of ACSR/AC

Figure 4 - Wind pressure test results

4.2. Snow Accretion Characteristic

[Test method]

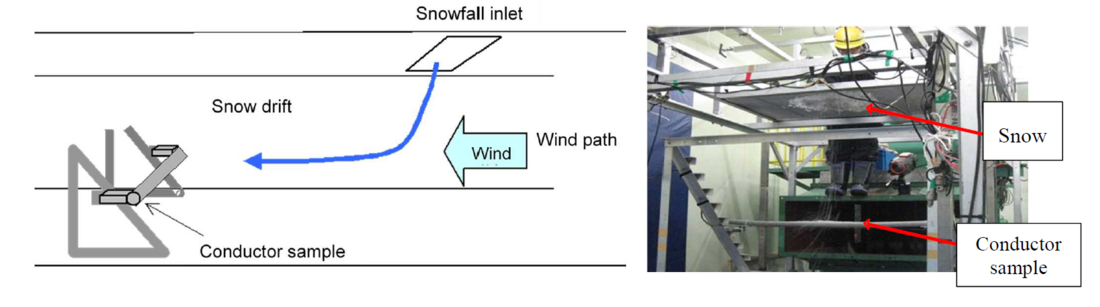

Using wind tunnel test equipment in Fig. 5, we conducted an artificial snow accretion test under the following weather conditions, in which standard power lines are prone to having snow tubes (Heavy wet snow accretion situation) formed on them: a wind speed of 6 m/s, snowfall intensity of 3 to 4 mm/h and air temperature of 2°C. Conductor is placed in front of the wind tunnel outlet, and snow falling from the snow outlet is carried by the wind and adheres to the conductor. After a certain amount of snow has accumulated, snow falls off. This test is continued until the snow has fallen off. we measured meximum snow accretion weight before the snow has fallen off.

Figure 5 - Snow accretion characteristic test method

[Test results]

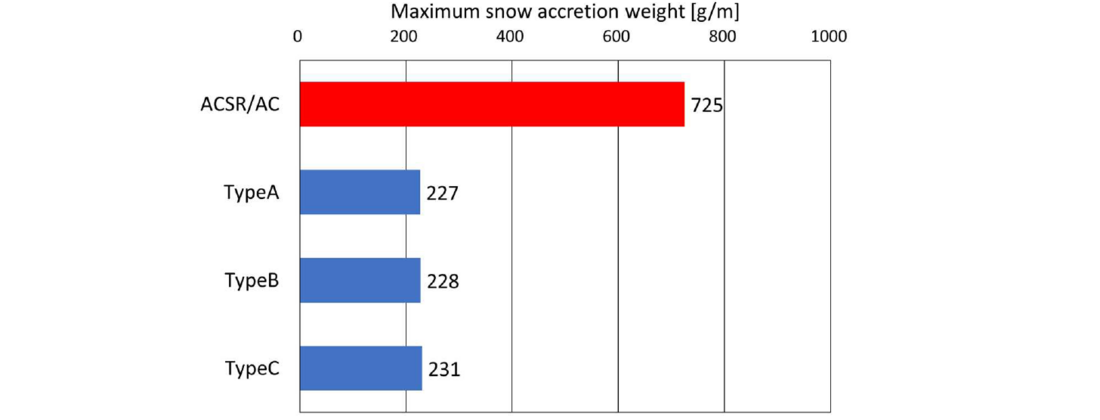

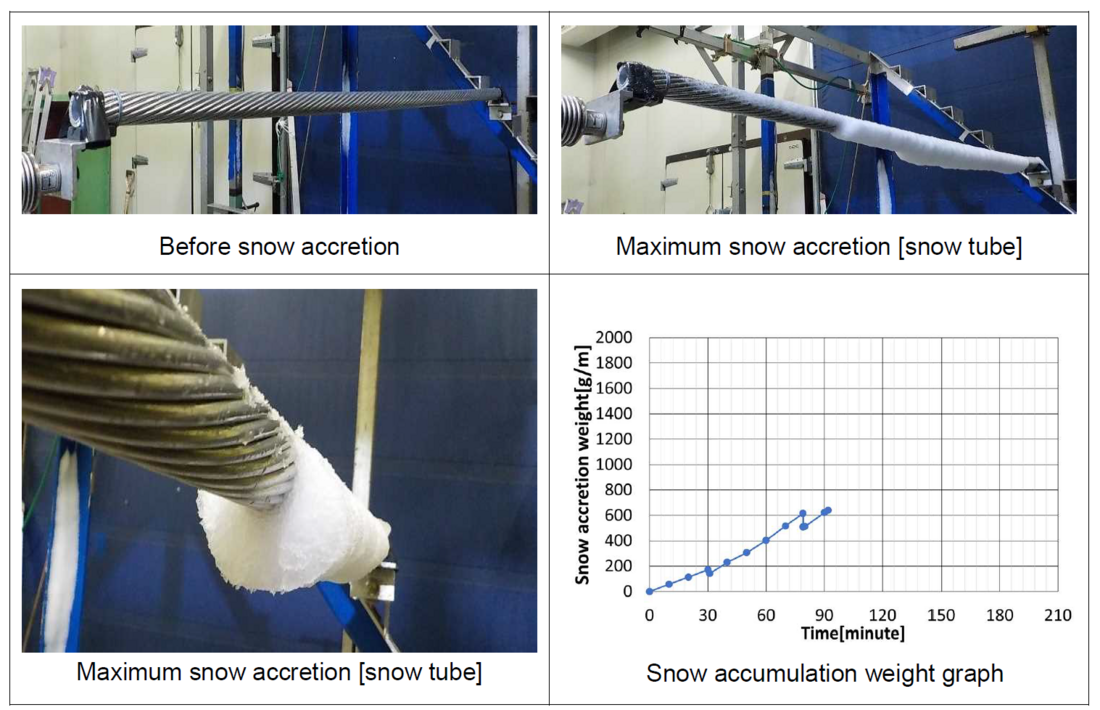

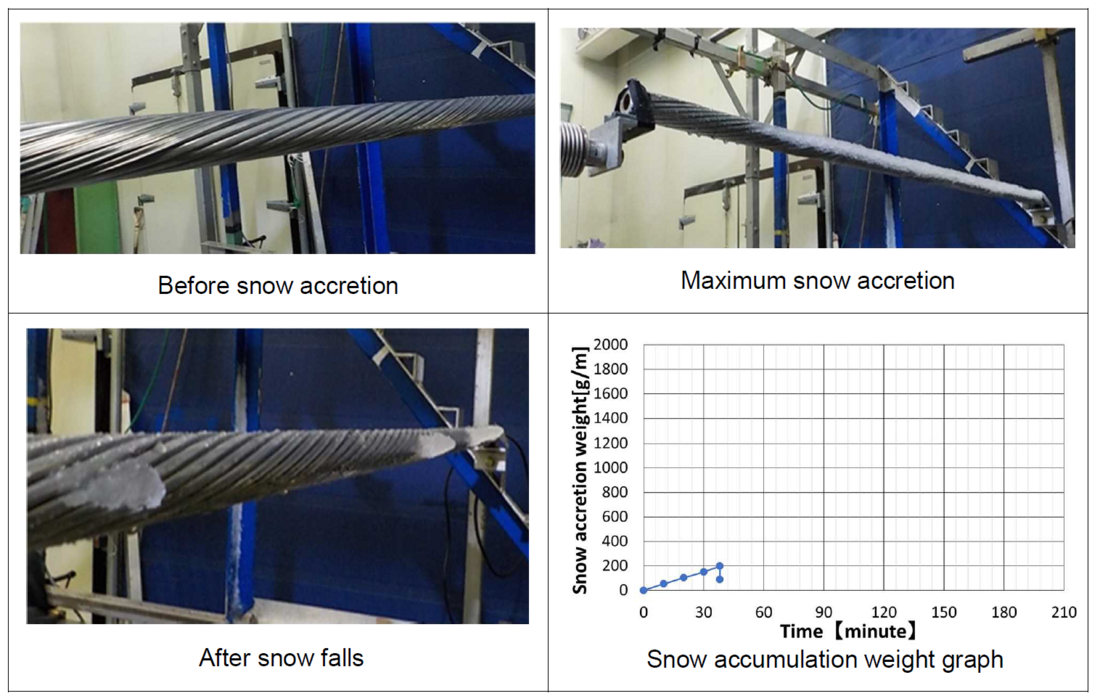

We verified snow accretion-proofing effects of roughly 70% for all types of conductors in Fig. 6. Multi-Function Conductor keep snow from forming snow tubes by making it fall when it slides along the stranded wires, precisely the effect that was expected when the power lines were first developed.

Figure 6 - Snow accretion characteristic test results

(N=3)

Figure 7 - Accretion characteristic test status (ACSR/AC)

Figure 8 - Accretion characteristic test status (Type B)

4.3. Corona Characteristic

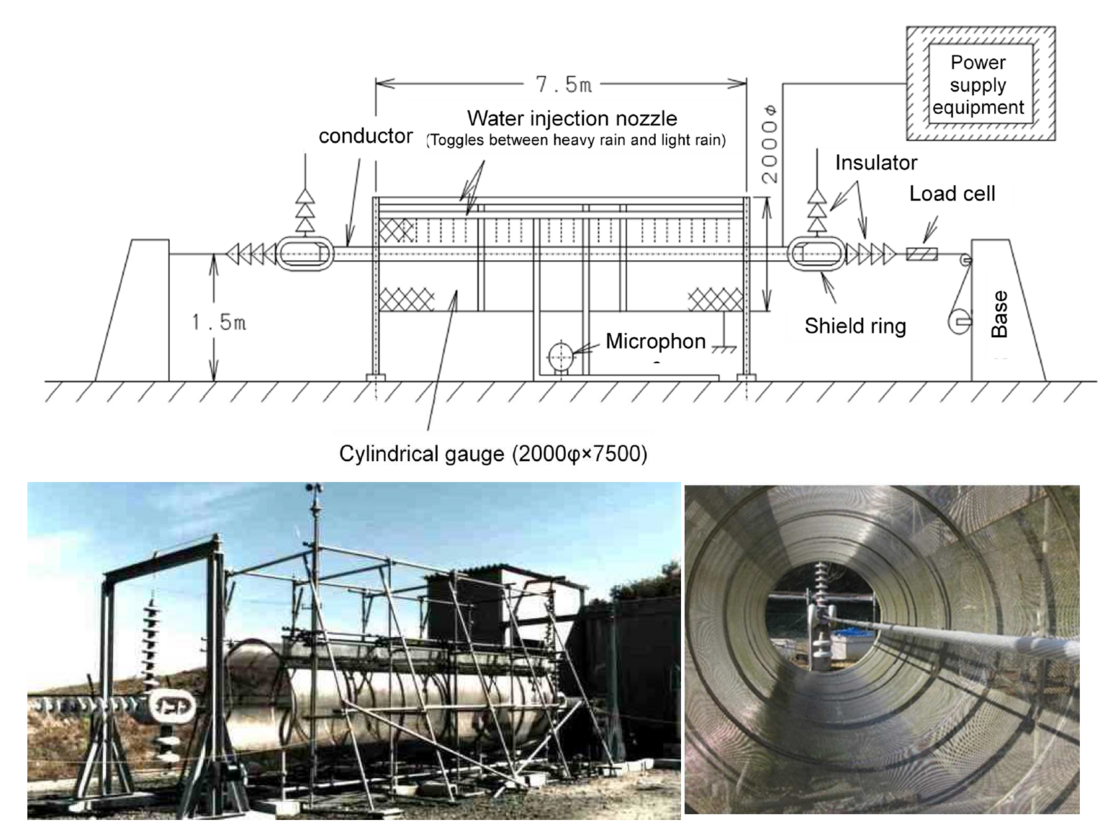

[Test method]

We charged voltage to conductor installed in a corona cage and measured corona noise using GMAX as a parameter in Fig.9. The items we measured were random noise and hums noise equivalent light rainfall* for each GMAX. *Equivalent light rainfall: The most problematic noise occurs during equivalent light rainfall. On actual transmission line, when sound occurs while it's "drizzling," complaints are prone to occurring due to the small background noise. In this test, we took measurements using the average of measurement values 1, 1.5 and 2 minutes after water injection was halted. For the transmission lines, we conducted a relative comparison between corona level, which has a noise level that is higher than that of ACSR/AC standard conductor but has still been accepted in Japan up to now. Additionally, we subjected all conductors to artificial aging treatment in order to exclusively verify the effects of their shape.

Figure 9 - Corona characteristic test method

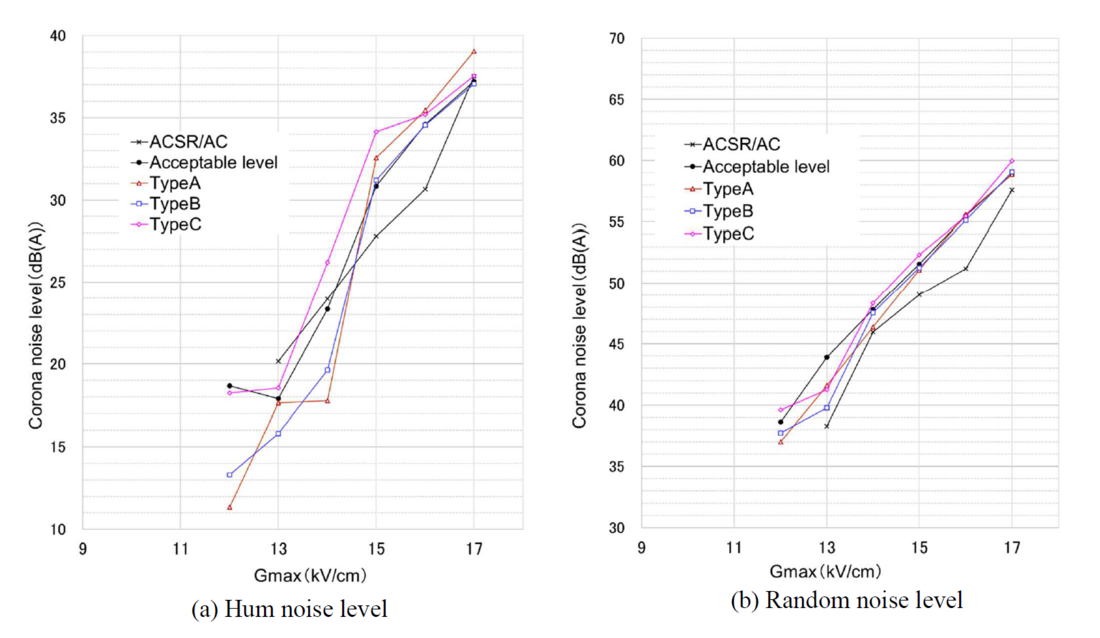

[Test results]

We were able to verify in Fig.10 that hum noise during equivalent light rain, which are the most prone to being the subject of complaints, rose over those for the ACSR/AC. For Type B, however, we verified hum noise that were equivalent to those for the corona noise level which has still been accepted in Japan at around GMAX 15 kV/cm. For Type A and Type C, the noise level is higher than that of the for the corona noise level which has still been accepted in Japan. In terms of random noise during equivalent light rain, Type A and Type B have noise levels comparable to those of the for the corona noise level which has still been accepted in Japan. However, Type C exhibits a noise level greater than that of the for the corona level which has still been accepted in Japan.

Figure 10 - Corona Characteristic result (equivalent light rainfall)

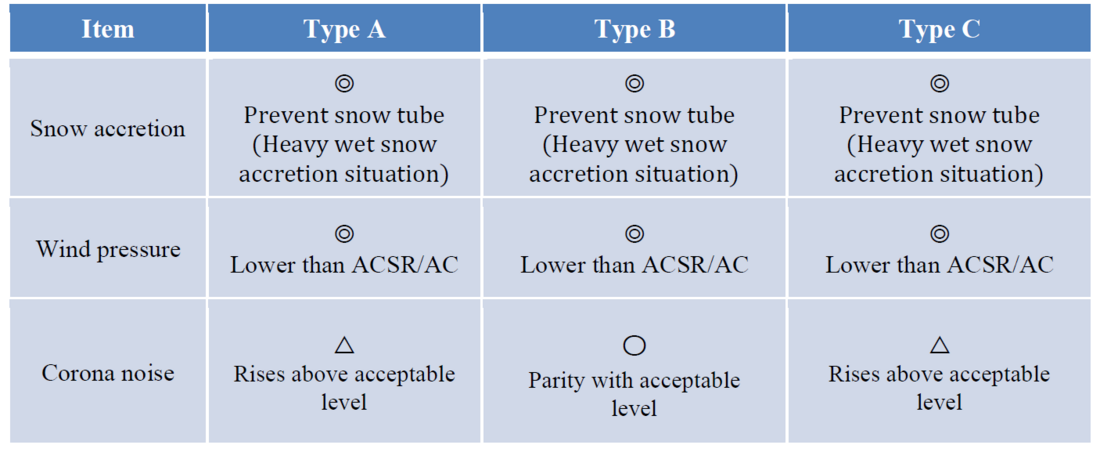

5. Conclusion

We introduced an examination of conductor shapes and the results of various characteristic tests conducted for the purpose of developing conductor with snow accretion-proofing functionality. We combined wire strand shapes with snow accretion-proofing performance as well as wire strand with low wind pressure effects to also equip the conductor we developed with those effects. Additionally, we verified that each performance metric was roughly equivalent to that of standard power lines. In the future, we plan to conduct a field test of Type B, which has superior overall performance among the three types of conductor subject to these tests and also enables conductor replacement due to conductor outer diameter and weight being the same as or lower than those of standard conductor ACSR/AC, in order to perform a final verification of its application.

Table 2 – Result summary