Enhancing Resilience with Mobile Substations: Lessons from TEİAŞ's Response to the Kahramanmaraş Earthquake

Authors

Tunahan AKBAŞ, Tamer ÖZKAHRAMAN, Mehmet İMERYUZ - EKOS Electric, Türkiye

Bilgehan TEKŞUT, Umut YENER - TEİAŞ, Türkiye

Summary

This paper examines the critical role of mobile substations (MSs) in rapidly restoring energy supply during emergencies, focusing on lessons learned from the 6 February 2023 Kahramanmaraş earthquake. By addressing the history of MSs, their operational capabilities, and the challenges faced in real-life disaster circumstances, the study highlights the importance of these systems in enhancing grid resilience. Drawing on the experience of the Turkish Electricity Transmission Company (TEİAŞ), the use of MSs during this disaster is analysed and important implications for future preparations are presented, especially for the expected “Great Istanbul Earthquake”. The study adopts a multifaceted methodological approach. A case study of the deployment of 4 154/33 kV Type A and 4 mobile distribution units by TEİAŞ during the Kahramanmaraş earthquake and their operational success and challenges is presented. The design and performance characteristics of TEİAŞ's MSs were analysed and supported by information from CIGRE technical documents. In addition, global best practices and technological advances in MSs were assessed and discussed in the context of Turkey's energy infrastructure needs. Strategic planning based on risk and impact analysis was conducted and recommendations were developed for more effective use of mobile substations.

Keywords

Mobile substations, resilience, transmission, grid restoration, emergency, disaster1. Introduction

Ensuring the continuity and rapid restoration of energy supply during large-scale emergencies has become a key priority for transmission system operators worldwide. Mobile substations (MSs), with their flexibility and rapid deployment capabilities, offer a vital solution in regions exposed to seismic risks such as Turkey.

Accordingly, TEİAŞ, who has long recognized the strategic value of mobile substations, has systematically expanded its MS fleet adapting to evolving grid needs through successive enhancements in capacity, design features, and deployment capabilities since 1996. Mobile substations have been utilized not only in emergency restoration scenarios but also to support planned maintenance activities, urgent power needs in cases where the construction works of substations take longer time than scheduled, where power supply needs to be secured in major important events such as international summits and conferences.

Following two devastating earthquakes on 6 February 2023, TEİAŞ mobilized mobile substations under extreme conditions, providing critical insights into both operational strengths and system-wide challenges. The operation faced significant challenges, including logistical delays, site readiness issues, and limitations imposed by the damaged distribution network.

This paper analyses TEİAŞ's mobile substation operations during the Kahramanmaraş earthquake response, focusing on the experiences encountered in field deployment, site commissioning, and load delivery under difficult conditions. Considering Turkey's ongoing seismic risks, especially the anticipated “Great Istanbul Earthquake”, this study proposes actionable recommendations for enhancing disaster preparedness. Beyond evaluating the immediate operational outcomes, the paper also explores critical areas for improvement, particularly regarding site preparation, integration of mobile substations with the existing grid infrastructure, and the development of more compact, manoeuvrable unit designs and strategic pre-positioning of mobile substations.

By synthesizing real-world operational experiences with international design principles, this paper aims to contribute to the evolving body of knowledge on emergency energy restoration and grid resilience, offering practical insights for transmission operators facing similar challenges worldwide. This paper suggests the design of MSs toward agility-optimized, modular units fit for modern unplanned emergency situations.

2. History of TEİAŞ and Mobile Substations

The Turkish Electricity Transmission Corporation (TEİAŞ) have commissioned mobile substations (MSs) since mid-1990s as critical tools for maintaining grid continuity during capacity expansions, planned outages, and emergency response situations. Turkey’s high seismic risk and geographically dispersed load centres have necessitated a flexible, rapidly deployable solution capable of minimizing disruptions to power supply across the transmission network. In this context, TEİAŞ has steadily developed its mobile substation, evolving both the scale and technical sophistication of its fleet.

2.1. Evolution of TEİAŞ-Design Mobile Substations

Despite partly relating to global standards such as IEC 62271 Part 202 and 205, the design, construction and testing of mobile substations are subjected to change related to the specific requirements imposed by the use-case. Therefore, much like transmission network operators globally, TEİAŞ’s mobile substation design and requirements have evolved primarily by the technological evolution of the GIS technology, the implementation of IEC 61860 as well as the changing demands of the Turkish grid.

The first MSs acquisition in 1996 featured two trailer units of 25 MVA. Successive procurements introduced pre-assembled bays, reduced manual coupling, and dual-trailer architecture to enhance speed and flexibility. TEİAŞ expanded its inventory in 2008 with two additional 25 MVA units. Due to the physical size and modular limitations of GIS technology at the time, the connection between the GIS and the power transformer had to be disassembled before transit and reassembled on site during each deployment. This process added significant mechanical workload and extended commissioning times.

A significant change occurred in 2015, calls for one or two trailer units [2]. The first unit that consists of one complete 154 kV transformer bay, including the power transformer itself (permanently coupled to the GIS, see Figure 1), that feeds a single 36 kV busbar consisting of one incomer and one outgoing bay together with protection and control as well as auxiliary systems. This first trailer unit, which designed to be used in a substation where there is an existing MV busbar whose incomer connects to the outgoing of the unit, is main piece required in every call. The second unit, which is optional, consists of a line-up of MV switchgear only that is made up of two incomers, five outgoings and protection and control as well as auxiliary systems. As such it is aimed at being used in conjunction with the first trailer unit or as a standalone MV distribution box independent of the first unit in HV / MV substations where the MV busbar is out of service or does not exist at the time of use.

Figure 1 - Permanent Coupling Contact of the Transformer and HV GIS

From the electrical configuration standpoint, the main trailer consists of one full transformer feeder at the High Voltage -HV (154 kV)- side, furbished with the 50 MVA transformer itself together with all switching equipment and instrument transformers packaged as a complete SF6 Gas Insulated Bay. On the other hand, the Medium Voltage -MV (36 kV)- side is designed as a line-up of again SF6 insulated switchgear consisting of one incomer (from HV side of the transformer) and two outgoings connected on a single busbar. The configuration of the second trailer is alike consisting of two incomers and five outgoings connected to one single busbar. One of these incomers is identical to the one on the main trailer being rated to be connected to the 36 kV winding of a transformer in an existing substation while the other incomer is rated to be connected to one of the outgoings of the main trailer when they are used in conjunction.

A notable recent design evolution introduced in TEİAŞ's 2024 procurement includes extended the stability against earthquake conditions by raising the value of vertical acceleration from 0.25g to 0.5g; and trailer units that can be demounted on site, offering increased flexibility in planned deployments and infrastructure support [2]. TEİAŞ has since raised the requirements on specific equipment to mitigate the risk by requiring 1 g horizontal and 0.8 g vertical acceleration. This development in design, allowing the trailer-mounted unit to be detached from its transport vehicle and remain on site, can be seen as a shift from the traditional Type A configuration, where all equipment remains mounted on a trailer during operation, toward Type B, which are typically installed more permanently on site and may be assembled or demounted similarly to conventional substations [2]. The technical brochure by the working group B3.41’s well-summarizes the extended features related to the classification of different mobile substation types in Table 1 below.

| Type | A (Emergency) | B (Intermediate) | C (Semi-stationary) |

|---|---|---|---|

| Transportable | Yes | Yes | Yes |

| Relocatable | Yes (frequently) | Yes (occasionally) | No (not intended for relocation) |

| Total deployment/reponse time | Short (Hours-Days)* | Medium (Weeks)* | Long (may be up to several years for large installations) |

| In-service time | Short (Weeks-Months) | Medium (Months-Years) | Long (Decades) |

| Design | Trailer-mounted | Container | Shelter |

| Standards | Many compromises | Few compromises | Very few compromises |

| Intended use | Unplanned/Planned | Planned/Unplanned | Planned |

| *It is assumed that the mobile substation is already available to the user for mobilisation | |||

2.2. Use case scenarios

Historically, TEİAŞ has deployed mobile substations primarily in planned operational contexts where flexibility and temporary power supply are required. Organized Industrial Zones (OIZs) have been among the most common use cases (Figure 3), especially in rapidly growing regions where demand can outpace the available transmission capacity. The growing industrial production scale of Turkey over the years has provoked a growing need for energy demand. In such deployments, mobile substations serve as interim solutions to meet rising power demands while awaiting permanent capacity reinforcements or substation upgrades – over 40 projects as of 2025.

MSs have also proven valuable in high-security or mission-critical settings requiring temporary network isolation. A notable example includes their deployment during the G8 Summit held in Antalya in 2015, where a mobile substation was used to ensure grid stability and operational autonomy at the venue. Such cases illustrate the role of mobile substations not just as substitute infrastructure, but as strategic tools for controlled reconfiguration of the transmission network in support of public safety, logistics, or national event planning.

In recent years, however, the scope of mobile substation use has expanded in parallel with growing grid complexity, increased distributed generation, and rising peak demand. This broader system evolution, combined with Turkey’s ongoing seismic risk, has elevated the importance of mobile substations in unplanned and high-impact emergency scenarios. The 2023 Kahramanmaraş earthquake served as a vital moment that affirmed the operational value of mobile substations in real disaster conditions, while also providing critical insights into 5 logistical and system-level improvements needed to further enhance their effectiveness in emergency deployments. The following section provides a detailed account of TEİAŞ’s mobile substation operations during the disaster, drawing lessons for improved emergency readiness in future high-impact scenarios.

Figure 2 - Planned Commissioning of 50 MVA TEİAŞ Mobile Substation and Distribution Unit

3. Operational Response to the Kahramanmaraş Earthquake

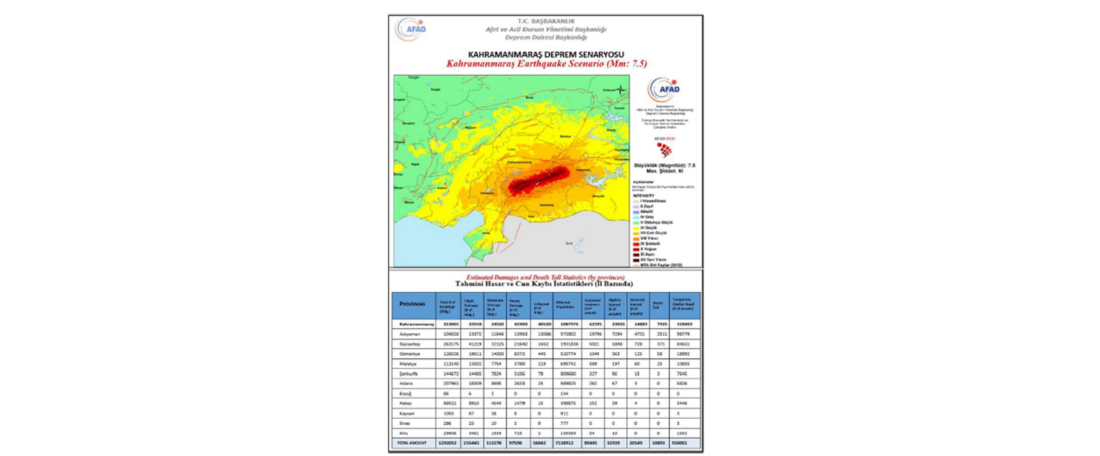

On 6 February 2023, southeastern Türkiye experienced two catastrophic earthquakes within a span of nine hours. The first, a magnitude 7.8 event, struck near Pazarcık in Kahramanmaraş Province, followed by a magnitude 7.5 earthquake near Elbistan. These twin seismic events, as mapped in Figure 5 caused widespread devastation across ten provinces, including Hatay, Gaziantep, Malatya, and Adıyaman, resulting in over 50,000 fatalities and displacing millions. The earthquakes produced a combined surface rupture exceeding 500 kilometres, primarily along the East Anatolian and Çardak faults. [2]

Figure 3 - Intensity Map of Kahramanmaraş Earthquake Sequence [3]

The scale and complexity of the disaster placed extraordinary demands on the national energy infrastructure including collapsed substations, damaged transformers, and severed high-voltage lines. Approximately %20 of the HV substations within the region were affected; while the following equipment were the most damaged;

- 400 and 154 kV bushings (11+11),

- 400 kV disconnecting switch (44)

- 400 kV autotransformer (2)

In response, the Turkish Electricity Transmission Corporation (TEİAŞ) initiated a rapid deployment of mobile substations to restore power in critical areas and support emergency recovery operations.

Figure 4 – Impacted Power Transformer Close to the Epicentre, 400 kV Substation

3.1. Logistical Delays, Site Readiness and Commissioning Challenges

TEİAŞ mobilized eight mobile substations and associated distribution units from regional centres in Ankara, Adapazarı, and Denizli to the affected areas. Deployment operations were carried out by three regional teams and included the transport and setup of four 50 MVA mobile substations and four medium-voltage distribution cabinets. In some cases, mobile units that had already been energized but remained unused were demounted and redirected. These efforts aimed to restore supply to critical nodes in damaged regions. However, the logistics of deployment were severely impacted by post-seismic conditions. Road infrastructure had sustained heavy damage, and mass civilian evacuations further congested access routes. For example, travel between Antakya and the Hatay substation—normally a 30-minute route—was reported to take over six hours due to uncoordinated traffic and emergency road closures. These delays significantly impacted on the response time and staging of mobile units.

Figure 5 - Transportation of TEİAŞ 50 MVA Mobile Substation

Site readiness presented another major challenge. In several locations, the lack of prepared foundation platforms and proper earthing systems delayed installation and raised safety concerns. While some mobile substations can operate without poured concrete foundations, the absence of adequate grounding necessitates temporary solutions to ensure safe energization. These improvised ground systems introduced further complexity to commissioning procedures and, in some cases, limited the substations' load capacity or required additional technical oversight. Additionally, the communication infrastructure in the affected region was severely disrupted, complicating coordination among TEİAŞ field teams and between regional control centres. In certain zones, mobile network coverage was unavailable for days, and reliable communication could only be established via landline connections in still-functional substations. This impeded synchronized deployment planning and delayed confirmation of site readiness for energization.

Despite these constraints, TEİAŞ successfully energized several mobile substations in a matter of days. However, the challenges encountered underscore the need for improved pre-disaster transport planning, standardized site preparation protocols, and enhanced communication redundancy for field operations. These findings are further contextualized by the performance limitations imposed by the distribution network itself, as discussed in the following section.

3.2. Distribution Network Impacts and Load Constraints

Despite rapid deployment, TEİAŞ was only able to deliver limited energy through its mobile substations due to extensive damage in the distribution network. In regions such as Hatay, Fevzipaşa, and Gaziantep, although mobile units were energized quickly, the available distribution infrastructure could only accommodate 3 to 5 MVA of load over several days.

This constraint highlights the need to consider more compact and lower-capacity mobile substation models, particularly for immediate post-disaster conditions where manoeuvrability and installation speed are essential, which will be further discussed with the lessons learned.

4. Lessons Learned and Strategic Recommendations for Istanbul Preparedness

As Turkey continues to prepare for future natural disasters—most notably the anticipated Istanbul earthquake—the role of mobile substations within TEİAŞ’s strategic planning is expected to grow. Experts estimate a 64% probability of a magnitude 7.0 or higher earthquake striking the city within the next seven years [2]. Given Istanbul's dense population and critical infrastructure, proactive measures are essential to mitigate potential negative impacts.

4.1. Site Preparation and Grounding Adaptations for Emergency Deployment

Deploying mobile substations—transformer trailer-set weighing approximately 160 tons— requires stable foundations, which are often unavailable in post-earthquake environments. During the Kahramanmaraş earthquake response, the lack of intact concrete platforms significantly delayed installation. To address this, a controlled field trial for the use of modular emergency foundation systems, such as portable aluminium roadway panels commonly used in military logistics or heavy-duty access systems, can be evaluated as a rapid-deployment alternative.

Figure 6 - Example of a Military Roadway Laying Vehicle [7]

Grounding requirements present an additional challenge. Current Turkish regulations [2] and [2] typically call for permanent grounding installations (Figure 10 shows 60x40 meter layout), which can be impractical in time-sensitive constraints of emergency deployment. While these standards are designed for permanent substations, mobile applications require more flexible solutions. To expedite safe energization in emergency deployments, portable grounding mats or surface-laid copper loops may serve as viable alternatives to conventional buried mesh installations, particularly where time or soil conditions prevent standard earthing methods [2]. Integrating these adaptable solutions into standard planning and updating regulatory frameworks accordingly would improve TEİAŞ’s ability to deploy mobile substations quickly and safely in future disaster scenarios.

Figure 7 - Grounding Layout of 2024 TEİAŞ 50 MVA Mobile Substation (cm) in acc. with [2]

4.2. From Capacity to Agility: Revisiting Substation Size in Emergency Scenarios

While high-capacity mobile substations are invaluable in planned deployments, their size and transport constraints can limit responsiveness in emergency situations, particularly in dense urban environments like Istanbul. A transition toward smaller, modular units with lower power ratings (e.g., 3–10 MVA) could improve manoeuvrability, reduce logistical complexity, and enable deployment in hard-to-reach areas. The feasibility of air-transportable configurations— whether by heavy-lift helicopter or cargo aircraft—should be considered, especially for critical load centres where road access may be compromised. This shift also calls for a revaluation of the design philosophy: instead of relying solely on large-scale units developed primarily for maintenance and grid reinforcement, future mobile substations should prioritize fast deployment, simplified interfacing, and modular integration into damaged networks. Similar strategies have been explored in other MS projects, where compact single-phase or trailermounted transformers were deployed to overcome logistical and structural limitations [2]. Embracing such emergency-oriented designs would enhance response flexibility and reduce restoration time following a major seismic event.

4.3 Integration of Mobile Substations into the Existing Istanbul Grid

Istanbul being a highly congested and populated city, the high-voltage substations are compact, indoor-type facilities using underground cable connections rather than overhead HV lines. This poses a significant compatibility challenge for TEİAŞ’s current mobile substation fleet, primarily designed for air-insulated switchyards with overhead line interfaces. In the event of a major earthquake, where substation access is challenging or component-level damage may occur, existing mobile units may not be immediately adaptable to the cable-terminated infrastructure prevalent in Istanbul, corresponding to 28 HV substation sites. To address this, there is a clear need to develop modular adapter interfaces that allow mobile substations to integrate with underground cable network. This may involve retrofitting existing mobile substations with suitable cable bushings or expanding future procurement specifications to include underground cable termination compatibility by design.

Additionally, further modularization of mobile substation architecture—such as separating the GIS and transformer components onto different trailers—can offer operational flexibility. A similar approach was implemented in National Grid’s 400 kV MS, which employed separate trailers for HV transformer and breaker units to enhance layout flexibility and expedite site adaptation [2]. In cases where only one component (e.g., the transformer or the switchgear) is damaged, deploying a partial mobile unit reduces transport constraints and speeds up restoration. This decoupled configuration also allows for more adaptable site layouts in spaceconstrained or uneven urban environments.

To support strategic MS deployment in Istanbul, a preliminary groundwork may correlate seismic fault zones and risk maps with infrastructure typologies—such as GIS substations, underground cable terminations, and transformer configurations—most likely to be affected, which can be linked further, through the findings in 2.2.2, to similar risk assessment of the distribution network. This mapping can help identify priority areas for developing or prepositioning emergency-compatible MSs, including air-transportable, modular, or dual-interface variants. TEİAŞ has since started working on developing solutions drawn from the earthquake data, such as increasing the durability requirements of HV equipment for earthquake conditions, evaluating switching to more durable resin impregnated paper (RIP) type bushings, integration of seismic isolators and coordination studies with AFAD. This study highlights the need for continued research, including scenario-based simulations, regulatory adjustments for emergency interconnection, and pilot testing of modular mobile substation concepts in urban environments. A future-focused program that combines engineering adaptability with systemic risk modelling will be essential to ensure that mobile substations evolve into a fully integrated component of Istanbul’s earthquake resilience strategy.

References

- Türkiye Elektrik İletim A.Ş. 154/33.6 kV, 35/50 MVA MOBİL TRAFO MERKEZİ TEKNİK ŞARTNAMESİ. 2014;

- CIGRE Study Committee B3. Mobile substations incorporating HV GIS. CIGRE Technical Brochure No. 907. Paris: CIGRE; 2023;

- Meltem Şenol Balaban, Canay Doğulu, Nil Akdede, Haldun Akoğlu, Onur Karakayalı, Sarper Yılmaz, et al. Emergency response, and community impact after February 6, 2023 Kahramanmaraş Pazarcık and Elbistan Earthquakes: reconnaissance findings and observations on affected region in Türkiye. Bulletin of Earthquake Engineering. 2024 Feb 7;

- English D. Istanbul to be hit by major quake in next 7 years with 64% chance, Kandilli Observatory professor warns [Internet]. https://www.duvarenglish.com/istanbul-to-behit-by-major-quake-in-next-7-years-with-64-chance-kandilli-observatory-professorwarns-news-61894. 2023. Available online

- Enerji ve Tabii Kaynaklar Bakanlığı. Elektrik Tesislerinde Topraklamalar Yönetmeliği. Resmî Gazete. 2001 Ağustos 21; 24500. [Erişim: 4 Mayıs 2025]. Online

- Enerji ve Tabii Kaynaklar Bakanlığı. Elektrik Tesislerinde Topraklamalar Yönetmeliği. Resmî Gazete. 2001 Ağustos 21; 24500. [Erişim: 4 Mayıs 2025]. Online

- The Defense Ministry will receive a folding road for the passage of heavy equipment in the swamps [Internet]. Военное обозрение. 2017 [cited 2025 May 1]. Online

- CIGRE Study Committee B3. 400 kV mobile substation design, development and site implementation: Experience of a transmission utility. CIGRE Session paper ref. B3-109-2018

- CIGRE Study Committee B3. Technical considerations regarding the design and installation of mobile substations. CIGRE Session paper ref. B3-210_2004